We’ve recently conducted research with a variety of schools to determine what their biggest maintenance issues are relating to doors and ironmongery. The most common answers were:

• Wear and tear

• Misuse

• Product quality

In a busy school or college environment, keeping the replacement costs of door hardware to a minimum is the ideal, and can be achieved by installing quality products that will last in high-use areas. When choosing products for your building it is important to consider three key areas in your decision-making, to combat the common reasons for replacing ironmongery.

1. Intended Use

If you know how users are interacting with a door, then the correct door hardware can be installed in the first instance or retrofitted to an existing door.

Through talking to our facility managers working in education environments, we’re told that misuse and malicious damage are more likely to occur in areas where students congregate, such as in corridors.

The main issues that arise are misuse of doors causing damage to door closers, swinging on the door, and slamming them closed and open against walls.

To combat these common issues, installing a door closer with backcheck function would reduce the chances of damage to the door, wall, and ironmongery by dampening any excessive opening force. Also, making sure all doors that have a door closer also have a door stop fitted, a low cost but effective item that is often overlooked.

By making a door easy to use, perhaps having them operate with pull handles and push plates rather than lever handles, can lessen the degeneration and deterioration of any mechanical components as they’re fit for purpose and fitted in the correct location.

2. Expected Traffic

At Door Controls Direct we would always guide you towards fitting the correct specification and quality of product, as the right product in the right place will have a longer life span and need less maintenance.

As well as the intended use, you also need to consider the type and volume of traffic that a door will experience. There would be no requirement to fit a heavy-duty EN 2-6 door closer to a seldom used office door, but we would suggest you consider for fire doors in high-traffic areas, installing an electromagnetic door closer with hold open function. This would allow for the free movement of foot traffic whilst ensuring the door closes automatically when the fire alarm is triggered and keeping the wear and tear of the door and ironmongery to a minimum.

Standard 100mm fire rated ball bearing butt hinges will be suitable for many applications but if budgets allow, some high-use doors may benefit from being hung on hi-load butt hinges. The overall load bearing of the hinge is often very similar but hi-load hinges are designed with longevity in mind, with low friction maintenance-free bearings.

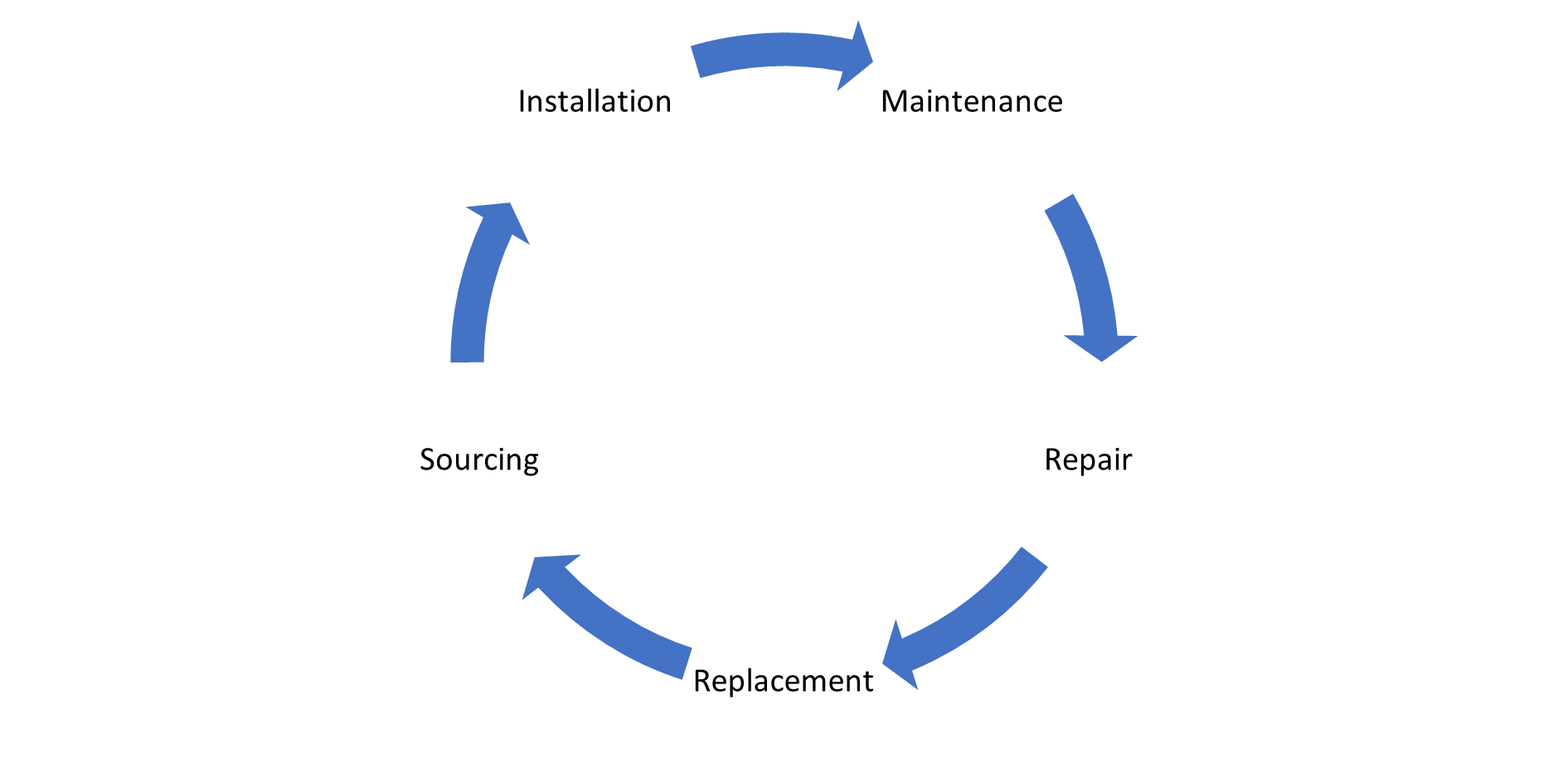

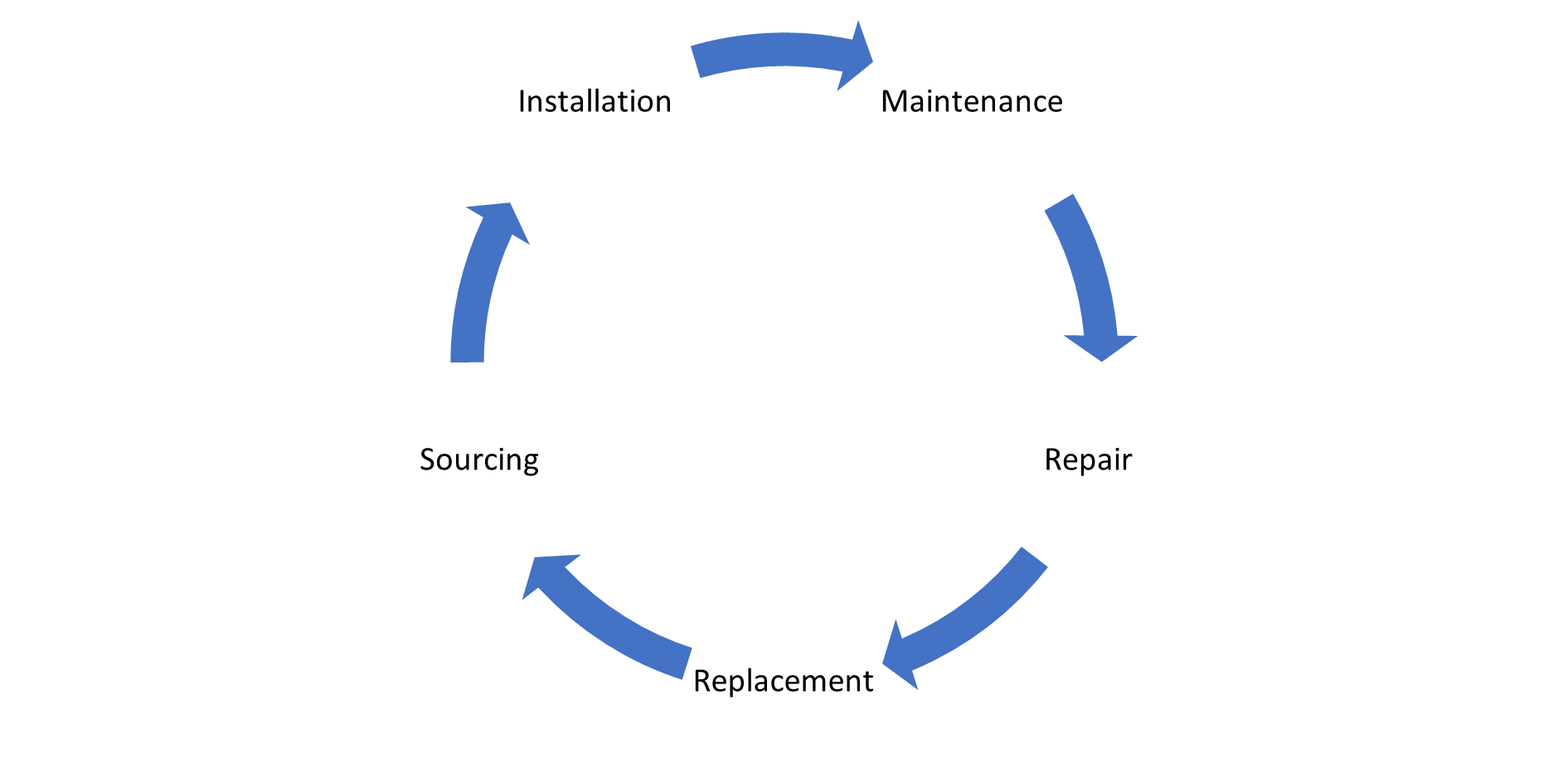

3. Life Cycle Costs

What is a product life cycle? It’s the installation, maintenance, repair, and replacement of a product. Whilst the initial cost outlay for an item of door hardware should always be considered, these other, on-going costs associated with the stages of the product life cycle, also need to be factored in.

Good quality products have been through rigorous design and manufacturing processes, which include a thought-out approach to their ease of installation and maintenance. Fixings work loose through use so a regular maintenance routine would ensure they remain tight. By investing in more durable door handles or lockcases in high-use or extreme use areas, the product components and assembly will be more robust, so the ironmongery is less likely to be damaged and need repairing.

In our research, customers emphasized the importance of having an expert available who can assist them in identifying the correct replacement products and having that replacement delivered swiftly, with great customer service.

Spare or replacement components are more readily available for quality door hardware such as overhead door closers than they are for some more budget products. So, when purchasing door hardware, look at spares available as these would be more economical than replacing complete units.

By making a considered product choice, from an architectural ironmonger who knows the industry, we can identify what you need, ensure it is fit for purpose, has a low life cycle cost, and deliver it quickly.

What Products to Consider?

We have outlined the most common items of door ironmongery and given our suggestion of considerations to be made when looking to maximise your ironmongery life cycle costs:

Locks

DIN standard lockcases are easy to change and replace as different function lockcases have the same footprint. The Arrone AR900 range are successfully type tested to BS EN 12209:2003, and are suitable for commercial use. Ensure that fixing bolts and screws are fitted to secure the lockcase in the door.

Handles

When fitting lever handles, always install with all the fixings supplied, both bolt fixings and woodscrews. Bolt fix through the lockcase or latch so the door handles are securely attached to the door, whilst the woodscrews prevent the rose from rotating. Also, consider the grade of use of lever door handles. BS EN 1906:2012 grade 3 is “high use by the public or others who have little incentive to exercise care” whereas the top level, grade 4, is “high use on doors which are subject to frequent violent use”.

Install pull handles on high-use doors rather than lever handles. There are fewer mechanical components to go wrong, plus they make the door easier to operate for users.

Closers

As we’ve already mentioned, install EMF hold open door closers to corridor doors and fire rated doors in high-traffic areas. They will improve the life cycle costs of the entire hardware as the door is held open and not in use.

Door closers with the correct functionality, such as backcheck, will prevent slamming, and doors opening against walls, whilst slide arm closers would prevent students from hanging off the door closer arms. Our customer research has also revealed that an investment in better quality units reduces the likelihood of closers leaking and needing to be replaced. The right specification of overhead door closer installed correctly should have a significant impact on your life cycle costs.

Hinges

Hi-load hinges have maintenance-free bearings that contribute towards reducing the cost of upkeep when compared to a standard butt hinge. However, grade 13 ball bearing butt hinges when correctly installed and maintained, have a test door mass of 120kg over three hinges. They will need a different level of maintenance but are still tested to 200,000 test cycles under BS EN 1935:2002. To prevent misuse, hinges can also be fixed using Torx/security fixings.

You can shop online with us 24/7, call, visit or email our branches, or preorder our new 2022 catalogue.

Top Tip - If you are experiencing excessive wear and tear of mechanical digital locks on high-use doors, which can stop some of the buttons from working correctly, then consider changing the access control to a proximity reader or have the door held open during the busiest of times.

Product Life Cycle

The initial outlay of cost in a quality, fit for purpose product is offset by the longevity of the product and the time spent on care and maintenance over the lifetime of the hinge, door handle, lock, or door closer.

As well as minimizing the impact on maintenance budgets by considering the whole life cycle of a product, sustainability and corporate responsibilities now also form part of the decision-making process when selecting ironmongery. Buying quality hardware from well-known brands will frequently mean the manufacturer and their supply chain are actively working towards being carbon-neutral, have sustainable sources for hardware, components, and raw materials, plus are routinely looking to make their products and processes more efficient and customer friendly.

By shopping with us at Door Controls Direct, we can provide you with expert knowledge, quality products, and exceptional value. We are here to help from specification to supply so get in touch with one of our team today.

Comments