I recently sat down with my colleagues Mike Drayton and Jordan Holleley to take a deep dive into their collective 50 years experience of locksmithing in the UK.

Who better to talk with about the key differences between commercial and domestic locksmithing than two Master Locksmith Association locksmiths who have worked for years on diverse projects, fitting, repairing, and replacing an assortment of products to a range of door types.

Join me as Jordan and Mike compare and contrast their diversity of experience within particular classifications of locksmithing, find out which side of the fence they come down on, and where they feel the future of locksmithing lies.

It’s all about the money, money, money

Before we go too far, we’ll address the elephant you’ll find in many rooms whether in a home, board room, or finance department – budget. With domestic work there can be an understandable tension around spend. It’s never usually planned work, so it is an unexpected cost, like car repairs. It’s not a pleasure purchase so whilst individuals are thankful for the work being done, there’s not a huge amount of gratitude because it’s money they’d rather not be spending.

Commercial jobs are covered by a company budget rather than an individual’s funds so is a reconcilable cost. There isn’t often any resentment around outlay for locksmithing work, security upgrades, or repairs. They could be budgeted on a quarterly or annual basis, with contingency for unplanned works; some level of maintenance or upgrade work is expected and anticipated.

Managing expectations

Retail work is very time sensitive and reactive. A quicker response is needed when there is a physical security issue at a domestic property. It’s seen as requiring an urgent response. Customers expect 24 hour call out services with someone on site ASAP, and need reassurance that products meet their requirements and that of their house insurance.

Commercial work is frequently scheduled ahead of time; it’s planned work whether it’s an upgrade, maintenance, or replacement. This suits our business model as we predominantly carry out commercial bench work that’s booked in advance. There are still some time and access restrictions such as an installation in the famous Stone Henge Visitors Centre that dictated a pre-dawn visit before the centre opened to the public. Those are few and far between though, with expectations of commercial work being undertaken weekdays during standard opening hours.

Preparation and considerations

The time required to prepare varies as domestic residential properties have easy access and minimal standards and regulations to be aware of. BS EN 3621 and BS EN 8621, along with BS EN 1303 will cover most domestic entrance doors, alongside PAS24.

Commercial premises are covered by a greater number of building regulations, fire safety standards, an awareness of general and site specific COSHH and health and safety details. They may also involve a schedule of works, a risk assessment or evaluation statement such as RAMS documents.

Whilst more predictable products are found in commercial and industrial facilities, the application can be more varied. Considerations need to be made for escape routes, final exit doors, fire compartmentation, use of spaces, and users. Layer this with budget, matching existing hardware, compliance, and time frames and commercial projects can be fairly involved compared to domestic jobs.

People problems

With domestic work, experience has shown it can be the people rather than the nature of the work that can be a little more problematic. Whilst issues are more run of the mill, such as a swollen door, a broken gearbox on a multipoint lock, or wear and tear on a cylinder barrel, how these issues are communicated can be tricky.

A layperson doesn’t have the terminology or jargon to describe a product or fault but in recent years technology has certainly helped address this. With an end user being able to email images and videos of a problem, we’ve found that a site visit can be more straightforward, we can go in pre-armed as far as possible. Once such common problem is cams spinning on the cheaper end of products, which for someone with no lock or locksmithing experience, would be difficult to describe over the phone.

Effective communication prior to a site visit can lessen any anticipated hostilities or frustrations but it doesn’t eliminate it. Working on sheltered housing or in mental health institutions over the years we’ve both experienced instances of verbal abuse, and on one site, being physically engaged with by a patient. And with residential work, people tend to be quite guarded. There has been bad press around ‘cowboy’ locksmiths, charging through the nose and conducting substandard work. Expectations need to be managed.

Scope and scale

Commercial projects have a huge variation in size and scope. Domestic locksmithing could be one door or a handful of locks to ground floor windows. Commercially, you could be dealing with a multi-floor, multi-building, or multi-site project.

Our customer base often has large sites which dictate a need for having their own maintenance teams or departments. Facilities managers ensure a lot of maintenance work is done in-house. In these instances, we get called in for the more specialist side of door hardware and security products. This could be from master key systems through to installing products to metal doors. There’s real variation with the scope of product when you’re looking at doors that others don’t want to get involved with due to their technicality.

As with residential work, technology helps no end. With clear and effective communication prior to a commercial site visit, our preparation can be much more targeted and efficient, understanding the scale of what we’re walking into. WhatsApp or facetime from site can even help to mitigate the requirement for site visits as you can talk someone through fault-finding and problem identification remotely. This can overcome a lack of specialist technical knowledge on site too.

Health and safety

If there was one main area of difference, it’d be this. With domestic work, we’ve found it’s a case of shoes off at the door and don’t let pets out. There’s not often much more than that to be aware of. With commercial and industrial sites there could be active, obvious hazards like forklifts working, differing requirements for PPE, having a greater awareness of your working practices and set up such as trailing cables across walkways.

We’ve also encountered verification and certification requirements in addition to the RAMS safety documents mentioned before. A DBS check for working in schools, or as we’re MLA locksmiths, an enhanced DBS check is required. In some schools, without an enhanced check, you must be chaperoned around the premises, another reason why thorough preparation is more of a focus for commercial locksmithing. We’ve had CSCS cards over the years but haven’t been asked to present them on site, but this could be due to the nature of the projects we work on.

Tip: We’d always suggest enquiring about site specifics as far ahead of time as is practical, so you’re not caught out.

Navigating logistics

This is an area that’s pretty different between these two branches of locksmithing. There is a wealth of different reasons for hold ups on commercial sites. A recent project at Childrens Hospice South West had to be dealt with very sensitively. Due to the very particular use of some of the rooms, noise was a key factor we had to be aware of and manage.

Operating on a work-in-progress site with mixed trades always throws up unexpected issues. A local project at Forston Clinic saw us fitting electric releases while painters and decorators were working in the same area. Between one day and the next, new flooring had been laid, barring our access to certain doors until it had cured. Locks clearly weren’t a priority. Some things you just can’t predict!

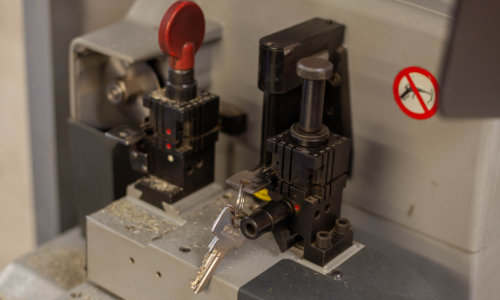

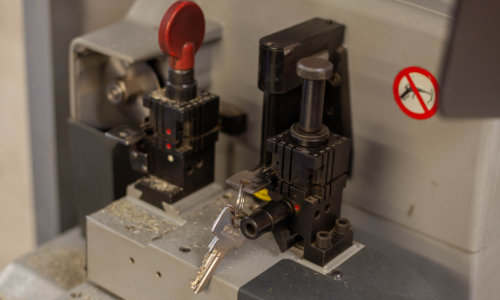

The mechanics and time

To generalise, the mechanics of both types of work are similar. The internal workings of many models and brands of mechanical locks are comparable no matter where they’re installed. It’s the issues with these common locking products that differ in our experience.

We have experienced more failures in domestic work as units tend to be left until they’re irreparable. There is also more gain-entry work with housing. Replacements tend to be swift and straightforward, swapping the broken gearbox or lockcase with a like-for-like unit. With our commercial work we see less failures and lock outs. FM, contractors, maintenance staff – they’ve all got great awareness and a degree of accountability for ensuring their locks continue to operate. Maintenance, repair, or replacement isn’t left until the last minute.

It's the opposite with after-sales though. We haven’t often seen call backs or teething issues on domestic work, experiencing supposed problems post-installation with commercial projects instead. It’s “supposed” because we’ve seen elements of scapegoating following site work, and it’s always on projects that are furthest away. Typical. A prime example is after installing good quality, robust Assa door handles with lockcases we had a call to say the door handles had “come off”. Returning to site to investigate, it was a clear instance of misuse and vandalism effectively, not an installation or product fault.

Tip: Our advice when it comes to effective time management would be to not overextend yourself with regard to geographical coverage. Having an e-commerce site and supplying products nationwide, we’ve ended up a fair way outside of what we’d class as our ‘area’, on small, low value jobs like fitting replacement ribbons on Salto units.

As a domestic locksmith, we’d say get to know your location. Local housing estates are likely to have the same brand and model of lockcase installed, so keep stock of those units, you can be in and out quickly, providing great customer service and building that all important local word of mouth.

Not playing favourites but…

Looking back over their experience with different types of locksmithing, Mike and Jordan were asked to make a choice – commercial or domestic work. Any guesses on what they chose?

Both went with commercial, and here’s why:

Jordan: “I enjoy the challenge of commercial work. I find it more engaging because there is a brief of sorts to work with such as balancing child safety in a school with safe and compliant egress. I get to use my imagination to provide different solutions in different facilities. It’s varied work, using quality products, and from a commercial perspective provides a greater return for us. You find yourself looking more in depth into regulations, products, and solutions on the market, tailoring that to building use, aesthetic preference, budgets, and time frames. It’s interesting to work on a breadth of different sites with scope to add my thoughts and experience to providing a unique solution for the customer and end user.”

Mike: “As Jordan’s said, I like being able to apply my experience to solving issues on site but also the almost multi-skill trade of being a commercial locksmith. It is a little different adjusting a multipoint lock to installing an Abloy EL560 solenoid lock, and we get to do both on the projects we deal with. Whether it’s return visits to the same site over a period of years, or different projects with the same clients, I enjoy the repeat business whilst retaining some variety. I’ve had the opportunity over the last 30 years to build a brilliant rapport with numerous contractors, on-site maintenance teams, and other local locksmiths.”

Moving forward

Whilst there is a love for commercial work, so we could show some bias here, it does seem more difficult to make a living as a domestic locksmith. Whilst it’s easier to train, with courses as short as a week to learn cylinder snapping and gaining entry, it’s become a saturated field focused on price matching. With no certification required, it’s seen by some as a part-time bolt on to another job, no longer a career with any longevity. New build houses have UPVC windows and PAS24 doorsets, with decreasing demand for secondary security products on older properties.

Tip: Get niche. Not simply the divide between domestic and commercial, but become a specialist such as with safes, auto locksmithing, or bench locksmithing. And adjust your expectations to your area. There’s more growth and progress to be made in commercial, particularly if you are looking to aggressively chase maintenance contracts, but can your geographical area sustain it?

By becoming niche, you can identify areas to expand into that may not be sufficiently covered. At Door Controls Direct we’ve begun FDIS qualifications to offer additional advice and services to our existing customer base. Make it easy for your customers – provide a service that covers all their doors and controlled access points and there’s no need for them to look elsewhere.

It’s clear that the locksmithing landscape is as diverse as it is dynamic. The distinctions between commercial and domestic work—ranging from budgeting and client expectations to logistical and health and safety considerations—highlight the unique challenges and rewards each sector offers. The evolution of technology has notably transformed our approach, allowing for a future where specialisation and strategic adaptation are key to thriving in the locksmithing profession.

Comments